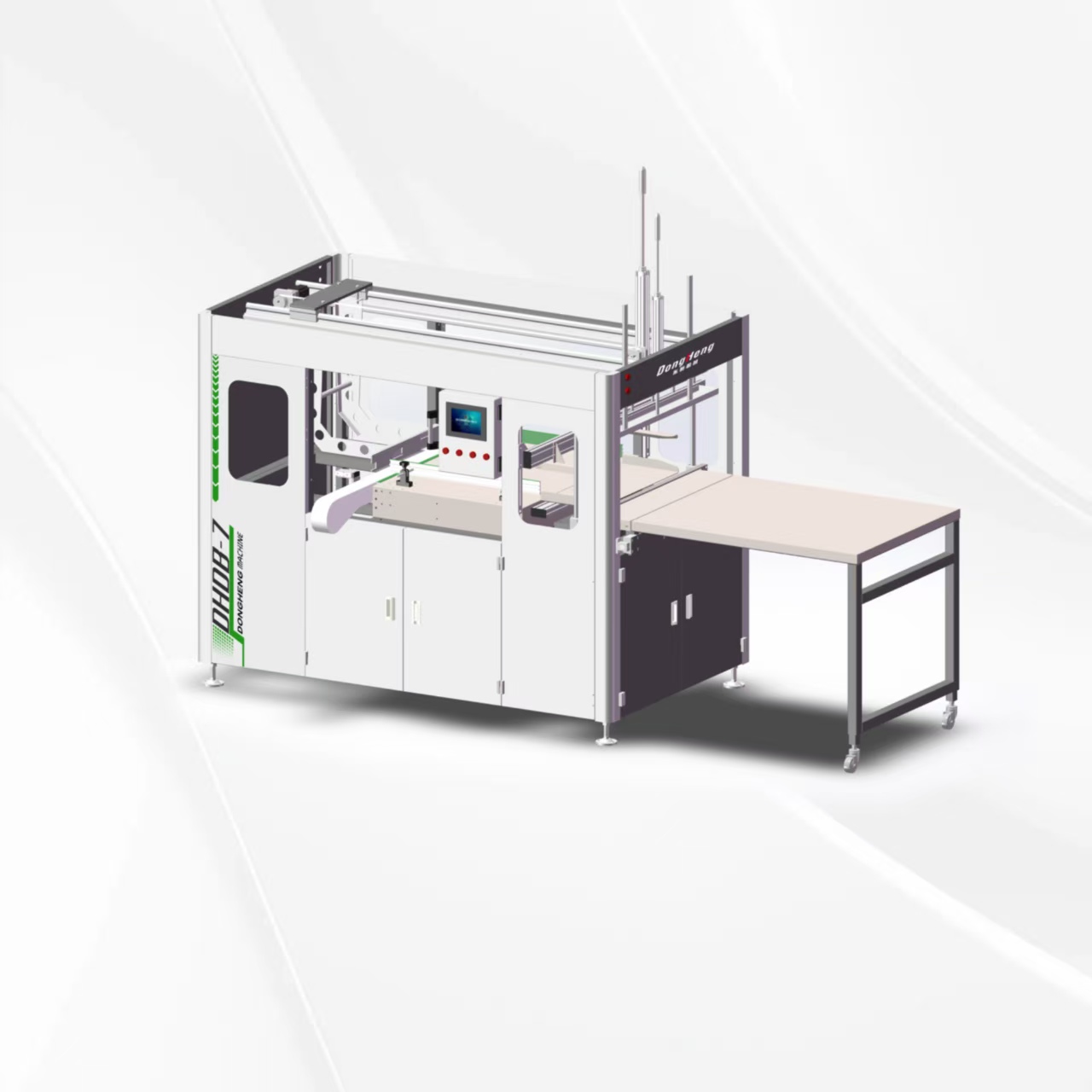

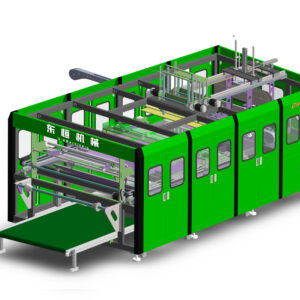

High-Capacity Automatic Bottle Bagging for Empty Plastic Bottles

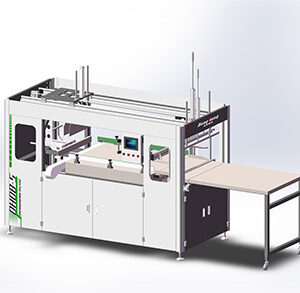

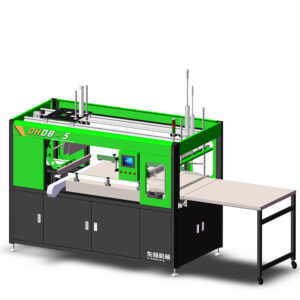

The DHDB7 automatic bottle bagging machine is specially designed for empty bottle packaging and high-throughput production lines. This model delivers superior performance for factories handling large-volume containers while maintaining precise and stable bagging quality.

Using Comenster flat film technology, DHDB7 effectively prevents bag tearing and ensures consistent sealing even when handling tall or heavy bottles. The reinforced mechanical structure provides excellent stability, making it ideal for demanding industrial environments.

DHDB7 supports various large-size bottles, including wide-mouth containers, water bottles, edible oil bottles, and industrial packaging bottles. It is suitable for variable bottle sizes.

This automatic bottle bagging machine can be integrated with bottle blowing machines, air conveying systems, labeling machines, and palletizers, forming a complete unmanned packaging solution. Its intelligent design reduces labor dependency while improving packaging consistency and hygiene standards.

Advantages of DHDB7 Automatic Bottle Bagging Machine

-

Optimized for large and tall bottle packaging

-

High-speed and stable bagging performance

-

Automatic bag specification adjustment

-

Cold sealing knife with double sealing lines

-

Adjustable bag opening and feeding structure

-

Heavy-duty stainless steel bottle pushing platform

-

Touch screen operation with real-time diagnostics

-

Lower logistics and pallet costs through optimized packaging

-

Enhanced product hygiene and protection

Technical Parameters – DHDB7

-

Machine size: 3433L × 1300W × 2600H (mm)

-

Conveyor system: 85mm flexible conveyor (recommended)

-

Weight: approx. 0.7 tons

-

Bag supplying method: Manual bagging

-

Bottle change adjustment: Manual adjustment

-

Applicable bottle materials: PET, PE, PP, HDPE

-

Bottle feeding height: 1050 ±100mm (customizable)

-

Bottle feeding direction: Left / right adjustable

-

Adjustable bottle height: 75–290mm

-

Finished bag package length: 400–1500mm

-

Finished bag package width: 400–950mm

-

Production speed: 3 seconds/row (stable operation), 12 seconds for bag pushing

-

Power consumption: 3kW

-

Power supply: AC 3ψ 380V

-

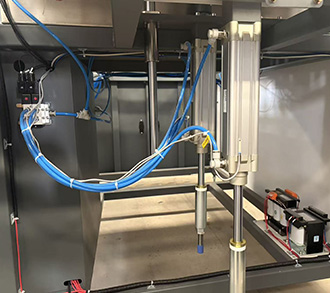

Air consumption: 0.6–0.8MPa, 0.5m³