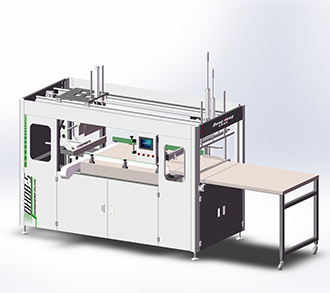

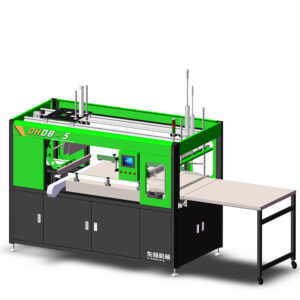

Automatic Bottle Bagging Machine – Model DHDB5

Efficient Semi-Automatic Solution for Medium-Speed Bottle Packaging

The DHDB5 automatic bottle bagging machine is a semi-automatic packaging solution designed to replace traditional manual bagging, significantly reducing labor costs while improving production efficiency. By integrating mechanized operation with reliable control systems, DHDB5 offers a stable and cost-effective choice for plastic bottle manufacturers seeking flexible packaging automation.

This automatic bottle bagging machine adopts Comenster advanced flat film bagging technology, which effectively reduces bag breakage and eliminates bag opening failures during operation. The optimized sealing structure ensures neat and secure packaging, making it suitable for continuous production environments.

DHDB5 is compatible with a wide range of bottle types and sizes, including mineral water bottles, edible oil bottles, cosmetic bottles, pesticide bottles, milk bottles, and wide-mouth containers. Bottle capacities typically range from 200ml to 1L, covering most daily-use plastic packaging applications.

The semi-automatic design allows operators to manually load bags while the machine directly connects with upstream equipment such as bottle blowing machines, air conveyors, or bottle unscramblers. Its compact footprint makes it ideal for factories with limited space while still maintaining reliable output.

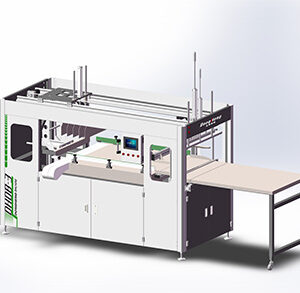

Key Advantages of DHDB5 Automatic Bottle Bagging Machine

-

Automatic adjustment of bag packaging specifications

-

Cold sealing knife heating with double sealing line design

-

Adjustable bag opening device for different bag sizes

-

Multiple bottle feeding methods available

-

Independent stainless steel bottle pushing platform

-

Touch screen control panel with real-time status display

-

Lower packaging cost compared to traditional tray packing

-

Improved hygiene by reducing human contact and cardboard contamination

Technical Parameters – DHDB5

-

Machine size: 3433L × 1300W × 2600H (mm)

-

Conveyor system: 85mm flexible conveyor (recommended)

-

Weight: approx. 0.7 tons

-

Bag supplying method: Manual bagging

-

Bottle change adjustment: Manual adjustment

-

Applicable bottle materials: PET, PE, PP, HDPE

-

Bottle feeding height: 1050 ±100mm (customizable)

-

Bottle feeding direction: Left / right adjustable

-

Adjustable bottle height: 75–290mm

-

Finished bag package length: 400–1500mm

-

Finished bag package width: 400–950mm

-

Production speed: 5 seconds/row (stable operation), 12 seconds for bag pushing

-

Power consumption: 3kW

-

Power supply: AC 3ψ 380V

-

Air consumption: 0.6–0.8MPa, 0.5m³