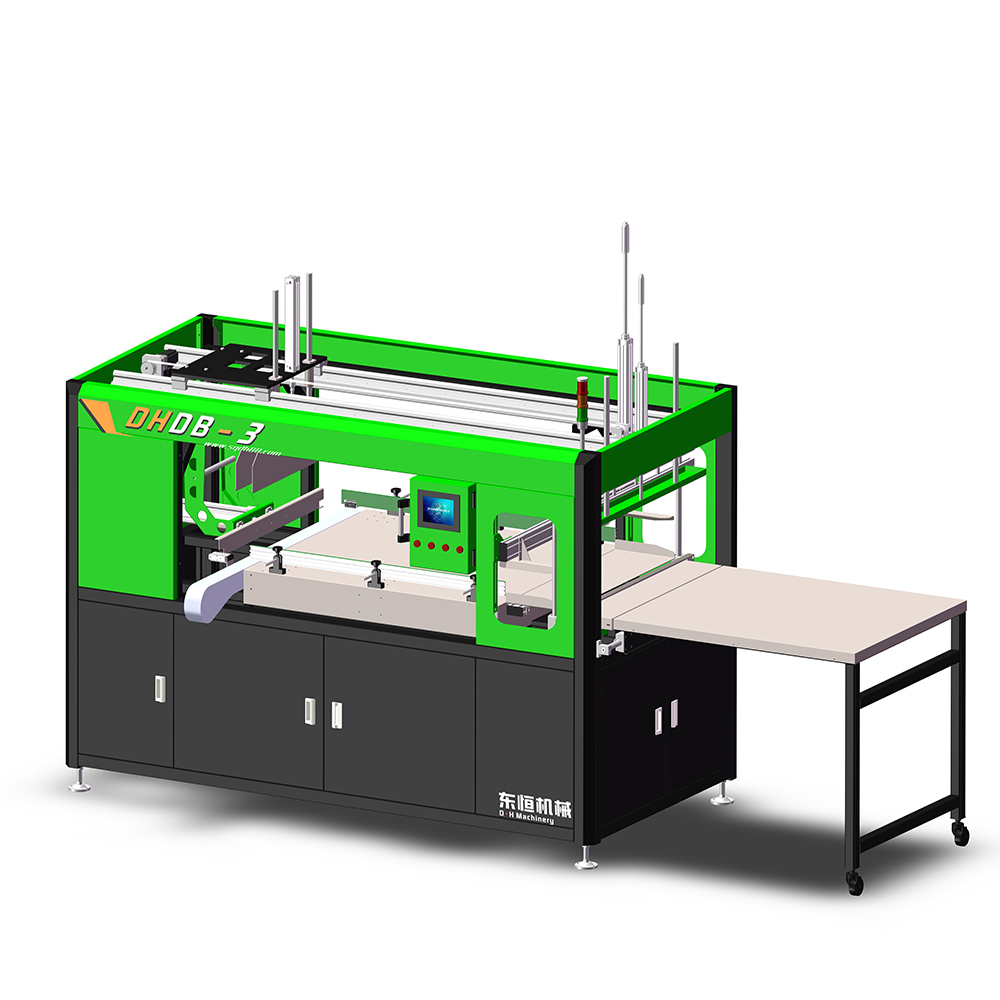

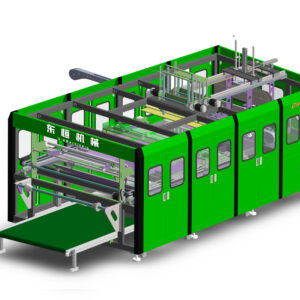

Compact Automatic Bottle Bagging Machine for Small & Medium Bottle Producers

The DHDB3 semi-automatic bottle bagging machine is designed for manufacturers pursuing compact layout, low energy consumption, and stable packaging output. Utilizing Comenster’s flat-film packaging technology, DHDB3 ensures a high sealing success rate and minimizes bag tearing issues commonly present in traditional bagging systems.

Designed for Versatility and Space-Saving Production Lines

Its small footprint makes DHDB3 easy to integrate into limited factory spaces while maintaining high packaging precision. It supports mineral water bottles, edible oil bottles, detergent bottles, and specialty wide-mouth containers from 200ml to 15L.

Main Features of DHDB3

-

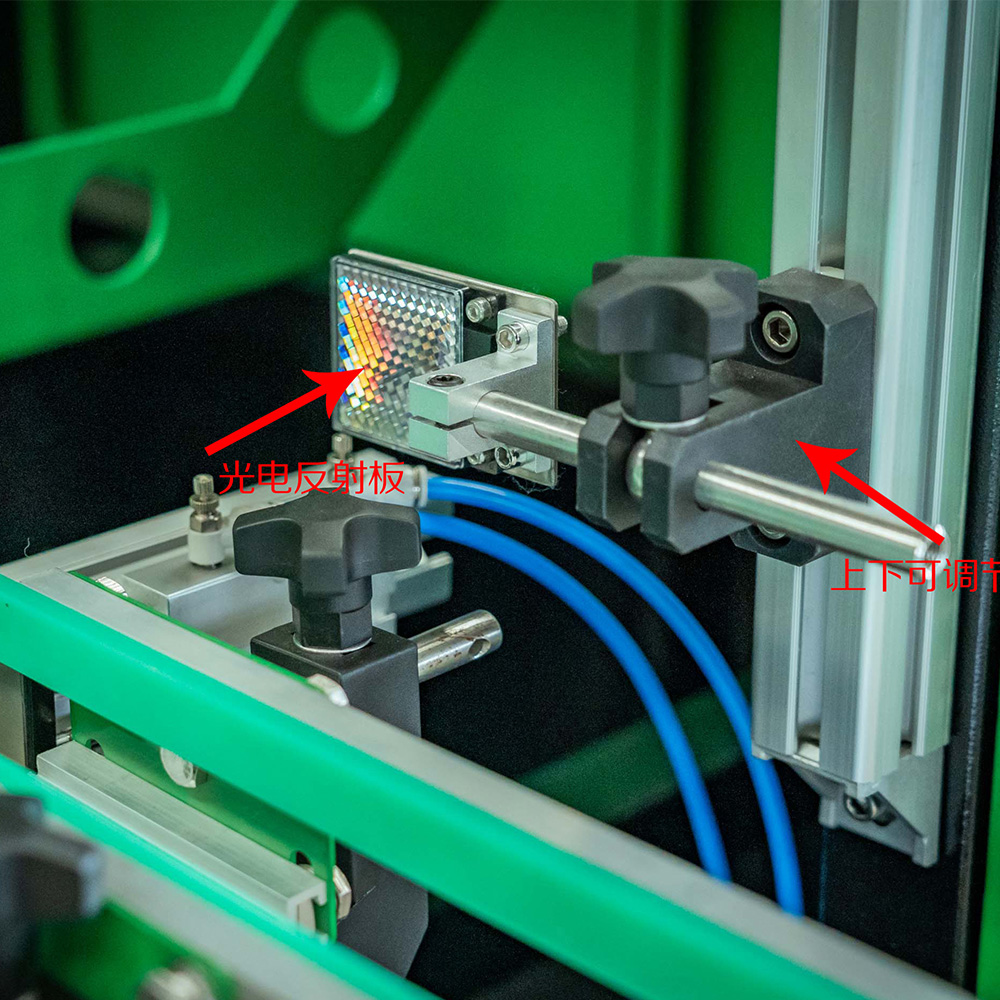

Automatic specification adjustment for different bottle packaging formats

-

Optimized thermal sealing knife system ensuring uniform sealing lines

-

Flexible bag opening module adaptable to various film materials

-

Multiple bottle-infeeding solutions for irregular shapes

-

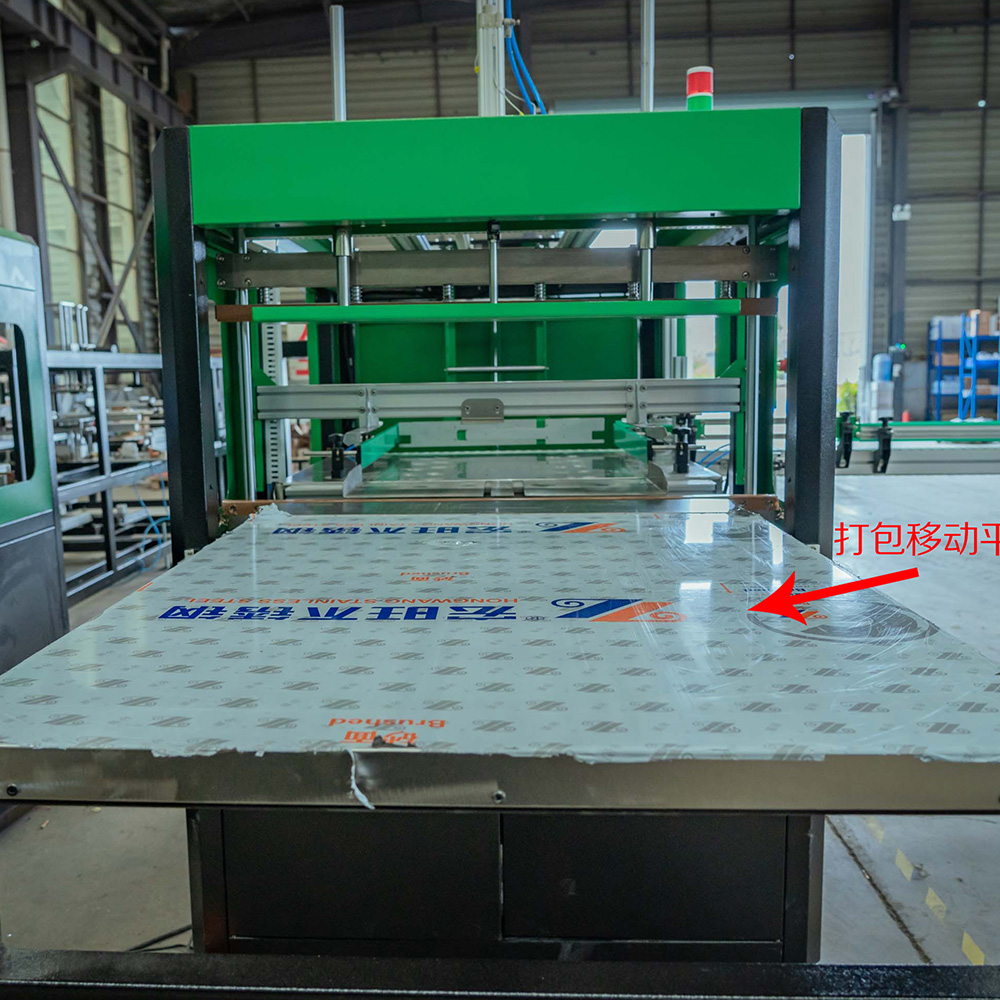

Reinforced stainless steel pushing system enhancing stability

-

Touch screen interface providing simplified and intuitive operations

-

Significant reduction in packaging material and pallet usage

-

Higher packaging density with more bottles per layer

-

Eliminates contamination from cardboard and manual handling

Technical Parameters – DHDB3

-

Machine size: 3433L × 1300W × 2600H mm

-

Conveyor system: 85 mm flexible conveyor system (recommended)

-

Weight: ~0.7 Tons

-

Bag supplying method: manual bag installation

-

Bottle change mode: manual adjustment

-

Bottle materials: PET, PE, PP, HDPE

-

Feeding height: 1050 ±100 mm (customizable)

-

Feeding direction: left / right adjustable

-

Bottle height: 75–290 mm adjustable

-

Finished bag length: 400–1500 mm

-

Finished bag width: 400–950 mm

-

Production speed: 5 seconds/row, 12 seconds for bag pushing

-

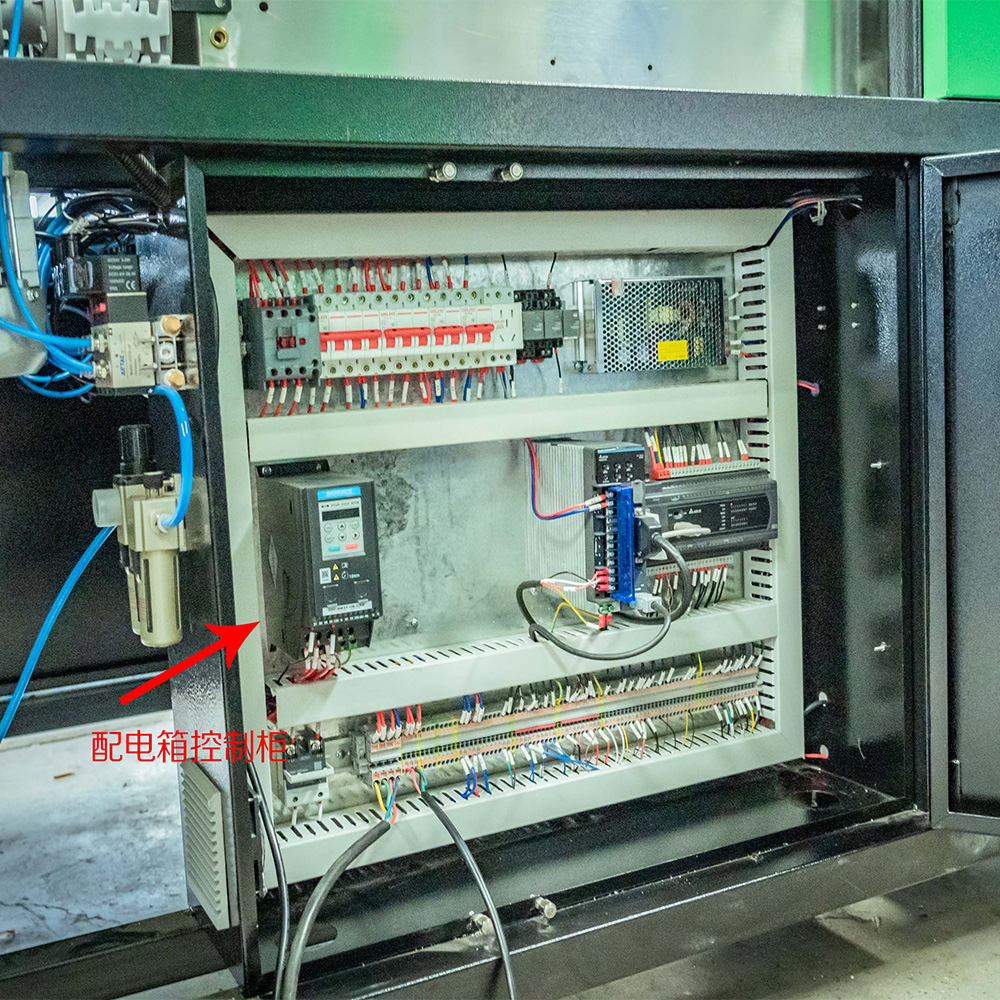

Power: 3 kW, AC 3ψ 380V

-

Air consumption: 0.6–0.8 MPa / 0.5 m³