Automatic Bottle Bagging Machine: Revolutionizing Modern Bottle Packaging

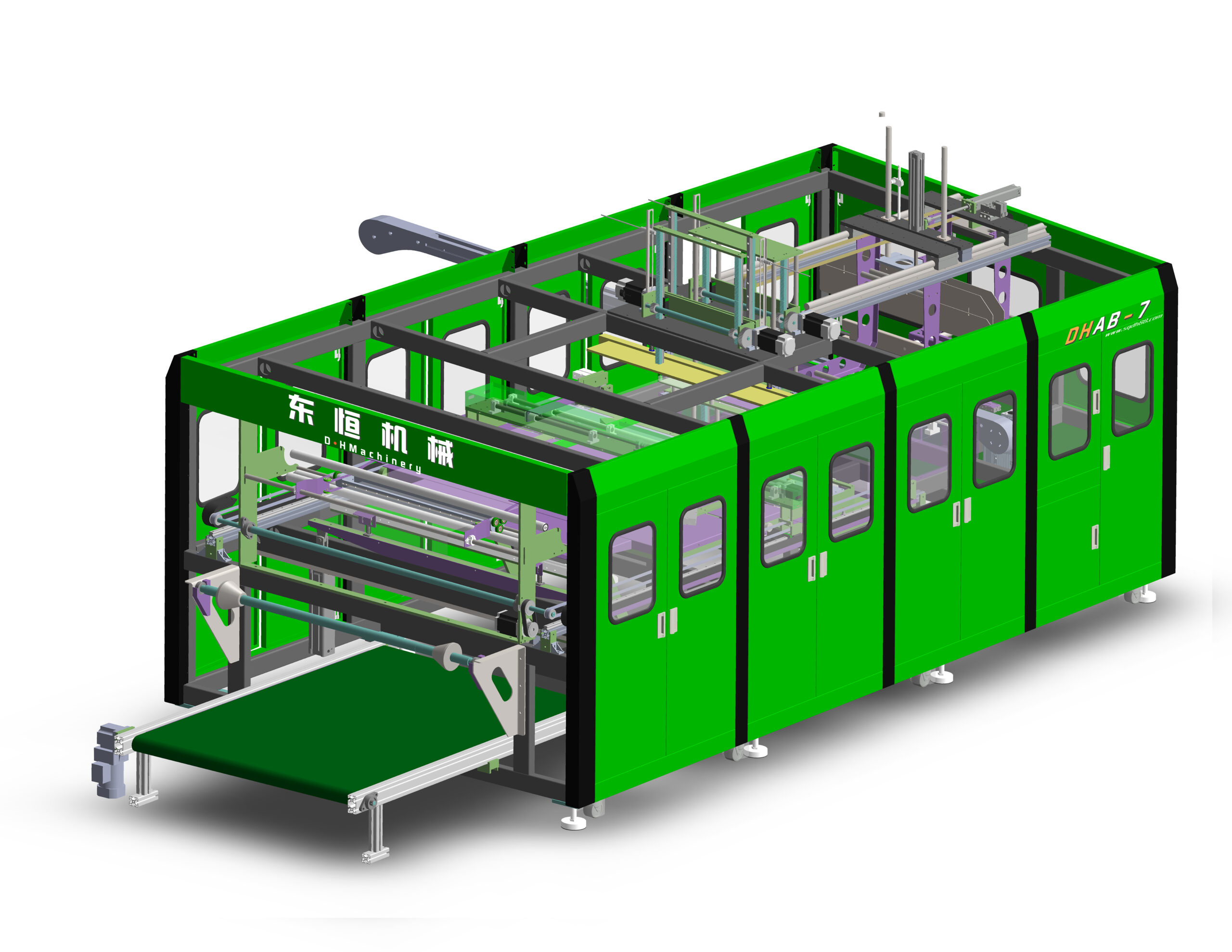

The automatic bottle bagging machine is a state-of-the-art solution designed for modern assembly lines, offering efficient, precise, and fully automated packaging for all types of bottles. It is ideal for industries producing PET, PE, PP, PVC, and other plastic bottles, supporting a seamless integration into your production workflow.

Seamless Integration with Existing Production Lines

Our automatic bottle bagging machine can be easily connected with upstream equipment, including bottle blowing machines, labeling machines, leakage testing machines, and visual inspection systems. This integration ensures a fully automated production process, significantly reducing manual labor and minimizing human error. With this machine, manufacturers can achieve a truly unmanned empty bottle packaging line, creating an intelligent, AI-driven plastic bottle factory.

Compact and Practical Design

The design of the automatic bottle bagging machine emphasizes compactness and practicality. It occupies minimal floor space while maintaining high throughput efficiency. The machine’s modular design allows for quick adjustments to accommodate different bottle shapes and sizes, making it highly versatile for varying production needs.

Advanced Features for Efficient Packaging

-

High-Speed Operation: Capable of processing hundreds of bottles per minute, reducing packaging time and increasing overall production efficiency.

-

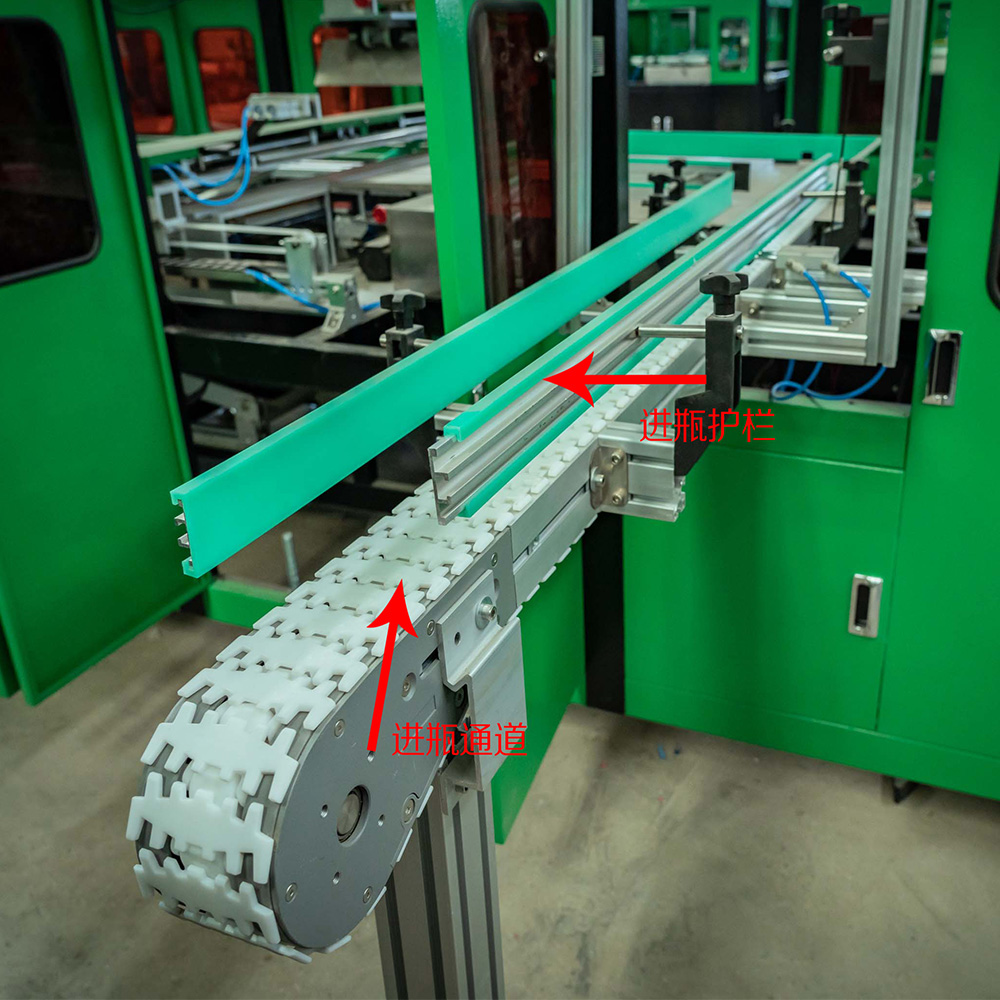

Intelligent Sensors: Equipped with advanced sensors to detect bottle presence, orientation, and spacing, ensuring precise bagging without jams or errors.

-

Flexible Bagging Options: Supports multiple bag sizes and materials, allowing manufacturers to adapt packaging according to market demand.

-

Safety and Reliability: Includes interlocks, emergency stops, and protective barriers to ensure operator safety and reduce downtime.

Benefits of the Automatic Bottle Bagging Machine

-

Labor Cost Reduction: Automating the bagging process reduces the need for manual handling and lowers labor costs.

-

Consistent Packaging Quality: Ensures uniform and accurate packaging, enhancing product presentation and brand value.

-

Scalable Production: Easily integrated into existing lines, the machine supports both small-scale and large-scale production without compromising efficiency.

-

Energy and Material Efficiency: Optimized for minimal energy consumption and precise bag usage, reducing waste and operational costs.

Applications

The automatic bottle bagging machine is widely applicable across various industries, including beverage, food, pharmaceutical, and chemical sectors. It is suitable for bagging bottles of all shapes and sizes, from small 200ml bottles to large 2L containers. Its adaptability ensures that manufacturers can maintain high production standards while accommodating changing packaging requirements.

Technical Specifications – Model DHAB3

| Item | Specification |

|---|---|

| Machine size | 5380L × 1950W × 2064H (mm) |

| Conveyor system | 85 mm flexible conveyor (recommended) |

| Weight | approx. 1.3 tons |

| Conveyor height | 1100 ± 100 mm (customizable) |

| Bottle height | 75–320 mm |

| Bottle material | PET, PE, PP, HDPE |

| Production efficiency | ≥95% for 8 continuous hours |

| Bagging method | Automatic plastic bag feeding |

| Maximum package width | 950 mm |

| Production speed | 3 seconds/row (stable), 12 seconds for bag pushing |

| Power supply | AC 3 ψ 380V |

| Power consumption | 4.5 kW |

| Air consumption | 6–8 kg, 0.3 m³ |

| Bottle feeding method | Double-row bottle infeed |

Why Choose Our Automatic Bottle Bagging Machine

Choosing our automatic bottle bagging machine means investing in a reliable, high-performance solution for modern bottle packaging. The machine combines advanced technology, ease of use, and long-term durability, making it an essential asset for manufacturers aiming to optimize their production lines and embrace intelligent automation.