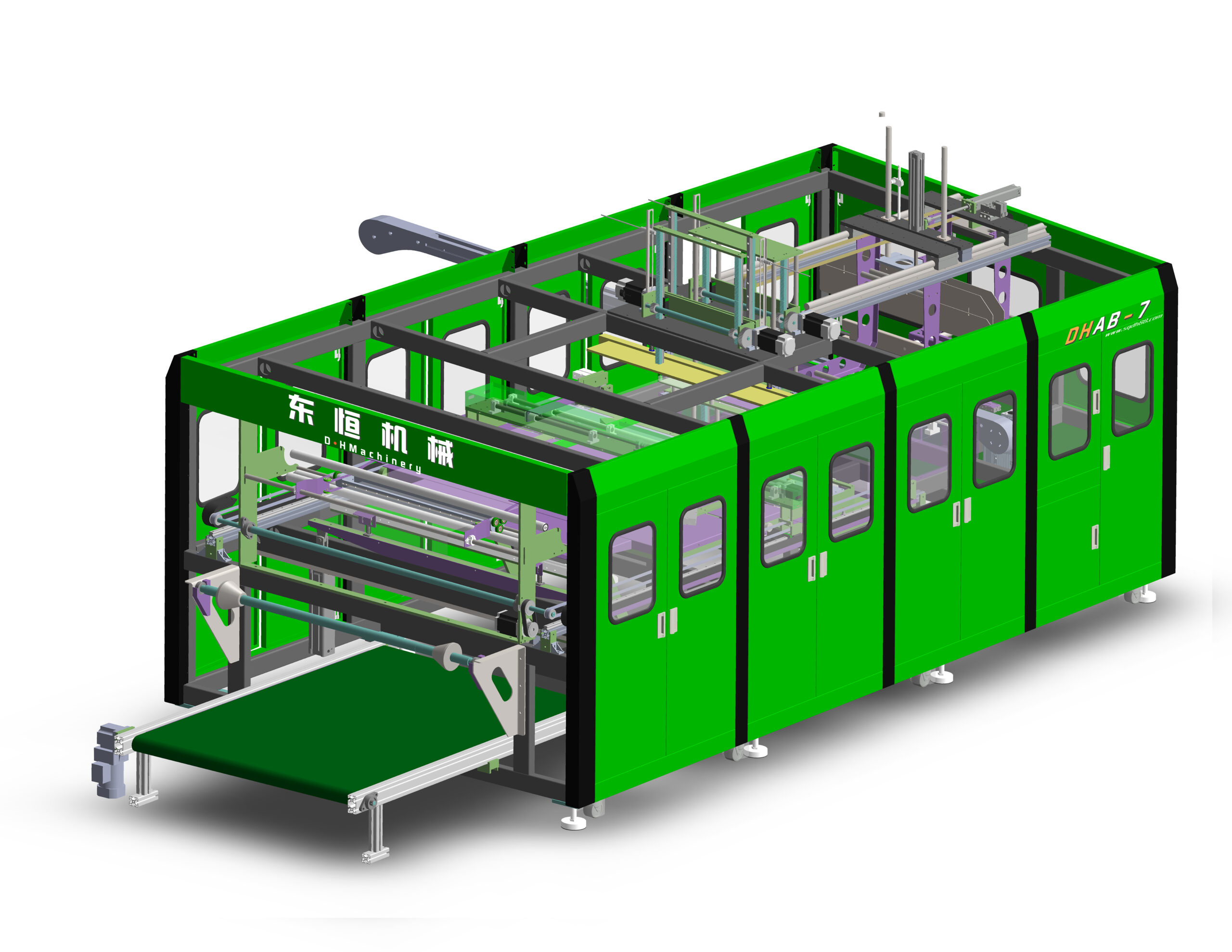

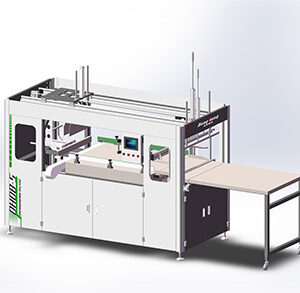

Automatic Bottle Bagging Machine – High-Efficiency Solution for Plastic Bottle Packaging

The automatic bottle bagging machine is a highly efficient and intelligent packaging solution designed for rapid bagging of various regular and irregular plastic bottles. It supports a wide range of bottle types such as mineral water bottles, beverage bottles, cosmetic bottles, medicine bottles, oil bottles and more. With the ability to adapt to different bag sizes, this machine is widely used in food, chemical, pharmaceutical, cosmetics and daily-care industries.

Compared with manual packaging, the automatic bottle bagging machine significantly improves efficiency and reduces labor and material costs. Operators only need to press a button to initiate fully automatic bagging, including bag feeding, bottle pushing, sealing, cutting and final bag discharge. This fully automated workflow ensures stable, clean and consistent packaging performance.

Key Features of the Automatic Bottle Bagging Machine

High-Speed & Stable Production

-

Production speed of 7 seconds/row, supporting continuous and efficient operation.

-

Equipped with advanced servo control for accurate and stable bottle pushing.

Advanced Sealing Technology

-

HWF double-line sealing technology ensures uniform, firm sealing with no breakage.

-

Sealing blade performance remains stable and unaffected by environmental temperature changes.

Fully Automatic Operation

-

Automatic bottle bag feeding — no manual bagging required.

-

Automatic rejection of inverted or incorrect bottles.

-

Automatic adjustment when switching between different bottle sizes.

-

Automatic material-shortage detection and intelligent waiting.

-

Automatic discharge of finished bags.

Applicable Bottle Types

The automatic bottle bagging machine is suitable for a wide variety of industries:

-

Beverage Industry: mineral water, soda, juices, tea drinks

-

Food Industry: edible oils, sauces, condiments

-

Cosmetics & Personal Care: shampoo, shower gel, lotion bottles

-

Pharmaceutical Industry: liquid medicine, disinfectant bottles

-

Chemical Industry: detergents, cleaning agents, solvents

-

Agricultural Products: pesticides, fertilizers and other bottled products

Its flexible bottle adaptability makes it ideal for both large factories and fast-growing production lines.

Technical Parameters (Model: DHAB7)

| Item | Specification |

|---|---|

| Machine size | 5380L × 1950W × 2064H mm |

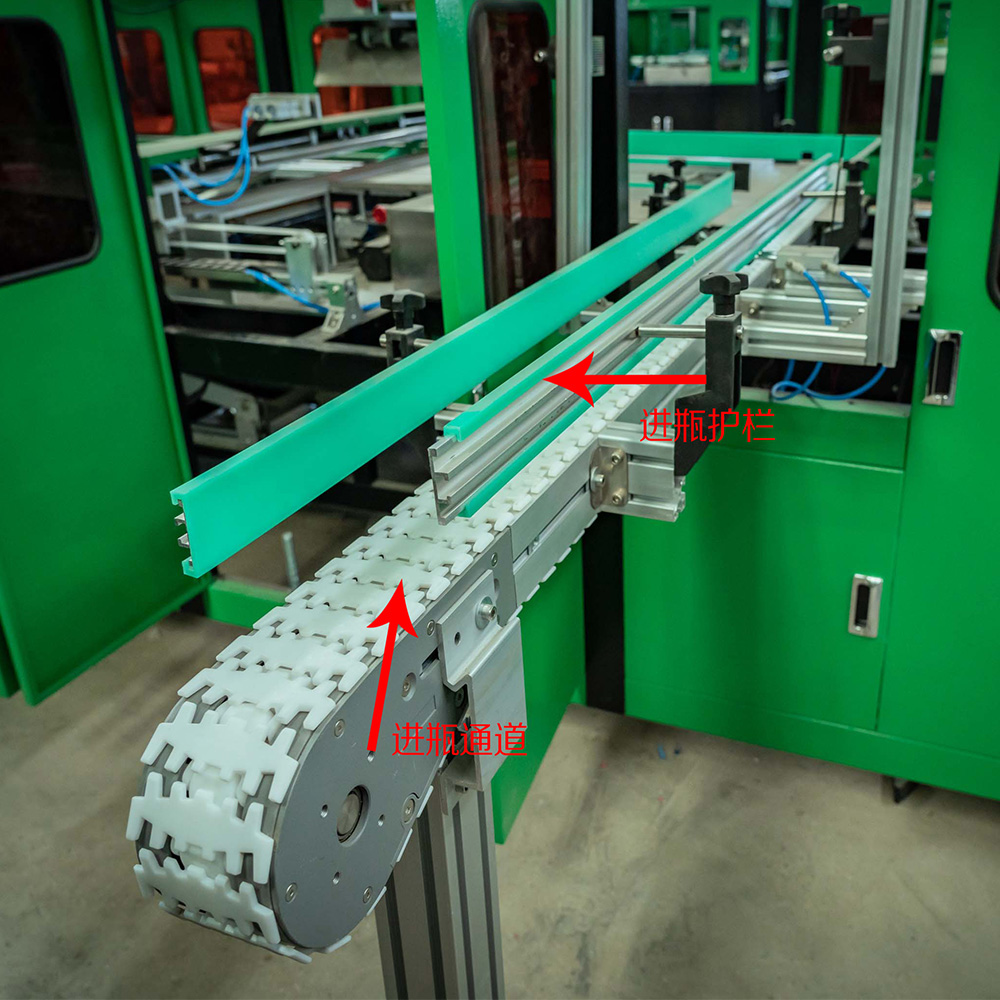

| Conveyor system | 85 mm flexible conveyor (recommended) |

| Machine weight | approx. 1.3 tons |

| Conveyor height | 1100 ± 100 mm (customizable) |

| Bottle height | 75–320 mm adjustable |

| Bottle material | PET, PE, PP, HDPE |

| Production efficiency | ≥95% over 8 continuous hours |

| Bagging method | automatic plastic bag feeding |

| Max. package width | 950 mm |

| Production speed | 7 sec/row (stable); 12 sec for bag pushing |

| Power supply | AC 3 ψ 380V |

| Power consumption | 3 kW |

| Air consumption | 6–8 kg, 0.7 m³ |

| Bottle feeding | double-row bottle infeed |

Why Choose an Automatic Bottle Bagging Machine?

The automatic bottle bagging machine offers the perfect combination of speed, durability and automation. It helps manufacturers:

-

Reduce labor costs

-

Improve packaging consistency

-

Increase line efficiency

-

Minimize bottle damage

-

Enhance factory automation level

-

Adapt to a wide range of bottle shapes and industries

It is an ideal solution for companies seeking to upgrade their packaging lines with a reliable, high-output automatic system.