Model 3710

High-speed bagging with precise bottle counting and gentle handling for up to 60 bags per minute.

Accelerate your manufacturing efficiency with advanced automation and reliable solutions. DongHeng delivers precision and scalability for your industrial needs.

Explore our advanced bagging machines designed to optimize your plastic bottle packaging process with precision, efficiency, and reliability.

High-speed bagging with precise bottle counting and gentle handling for up to 60 bags per minute.

Space-saving design with user-friendly controls, perfect for medium-volume packaging lines.

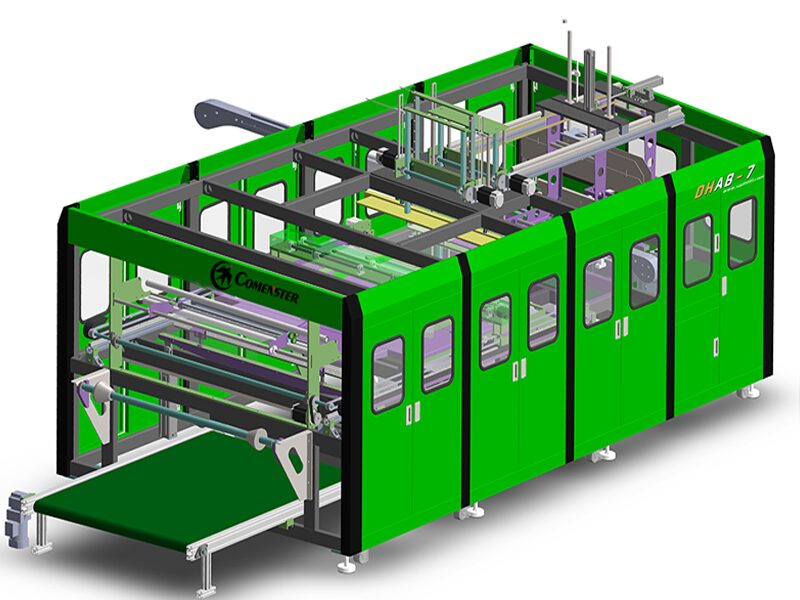

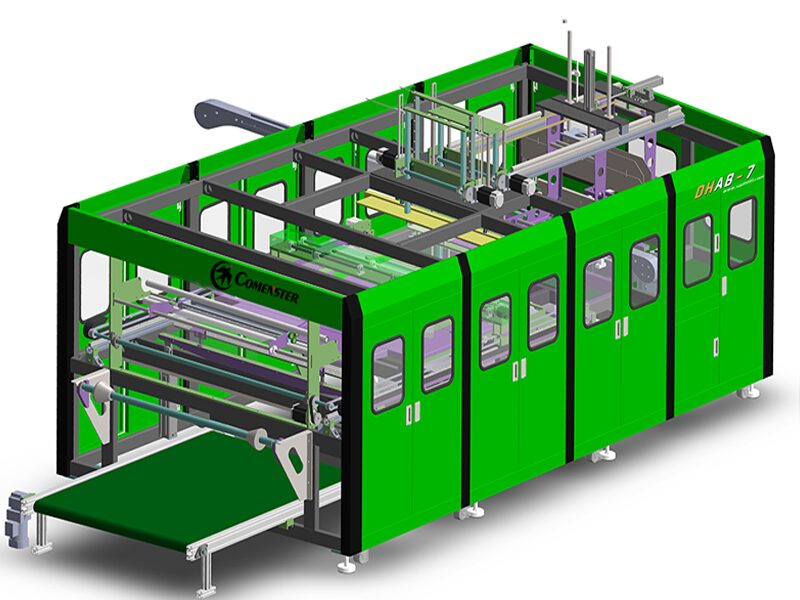

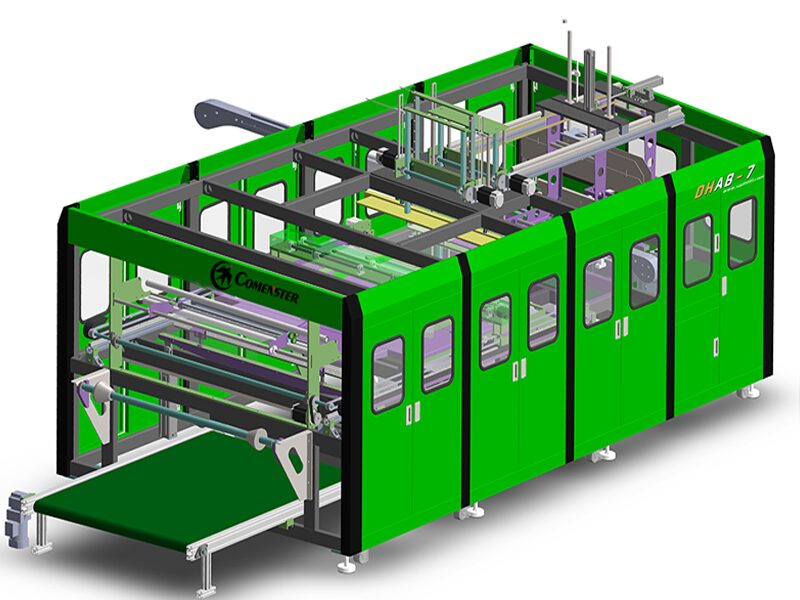

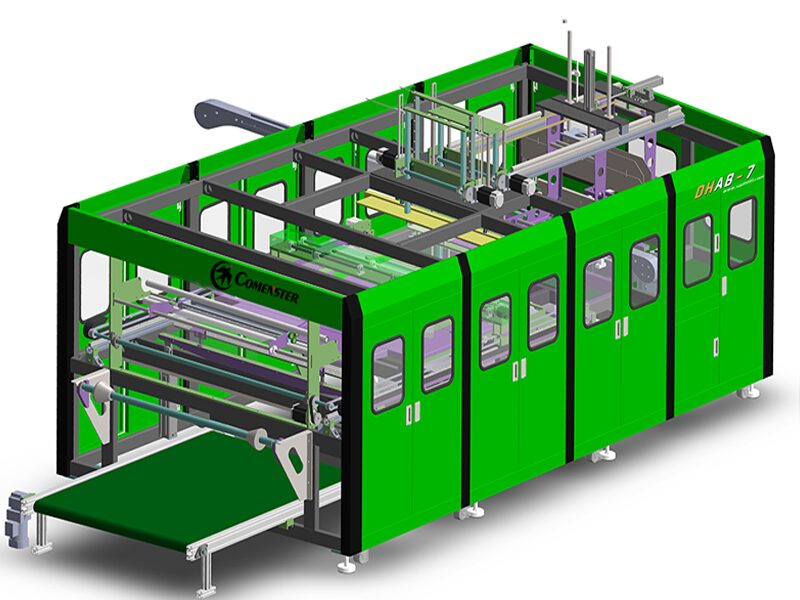

Fully automated operation with versatile bag sizes & rapid changeover for high-demand production.

Suitable for HDPE, PP, and PET bottles. High accuracy with low maintenance needs.

Designed for 1L to 5L bottles. High throughput with smooth PVC bag integration.

Flexible machine compatible with various bottle types and bag sizes for scalable operations.

DongHeng machinery adapts seamlessly to beverage, pharmaceutical, and chemical industries. Our systems optimize production efficiency and ensure compliance with strict industry standards.

Compatible with round, square, and custom-shaped bottles, including PET, HDPE, and glass variants. Our tooling adjusts precisely to diverse shapes and sizes for consistent handling.

Fully modular tooling enables quick changeovers and minimal downtime. DongHeng production lines integrate smoothly with upstream and downstream equipment for streamlined operations.

Advanced digital control technology ensures precise operation and optimal energy efficiency, enhancing overall productivity with minimal downtime.

Flexible modular architecture simplifies upgrades and customization, reducing installation time and adapting seamlessly to evolving production needs.

Integrated safety mechanisms ensure operator protection and comply with stringent industry standards, minimizing risk and liability.

Designed for easy access to key components, lowering maintenance costs and maximizing uptime through straightforward servicing procedures.

Discover how automatic bagging machines enhance efficiency, reduce labor costs, and improve product handling in packaging processes.

Automated systems handle high volumes with speed and precision, maximizing throughput.

Minimize the need for manual labor, lowering operational expenses and improving profitability.

Ensure consistent filling and sealing, reducing product waste and enhancing presentation.

Offer superior sealing and packaging that safeguards products from damage and contamination.

Automatic bagging machines streamline operations, providing a cost-effective and reliable solution for various industries.

Invest in automation to achieve higher productivity, lower costs, and superior product protection.

DongHeng’s modular design enables seamless automation expansion tailored to evolving factory needs.

Integrate systems effortlessly with advanced collaboration tools for comprehensive factory management.

Invest in long-term value with scalable upgrades that adapt to industry innovations and growth.

An automatic bagging machine is a type of packaging equipment that automates the process of filling bags with products. It is commonly used in industries such as agriculture, food processing, and chemical manufacturing.

The benefits of using an automatic bagging machine include increased efficiency, reduced labor costs, improved accuracy, and consistent packaging quality.

Automatic bagging machines can be used to bag a wide variety of products, including grains, seeds, fertilizers, animal feed, chemicals, and minerals.

There are several different types of automatic bagging machines available, including open-mouth baggers, valve baggers, and form-fill-seal (FFS) baggers. Each type is designed for specific applications and bag types.

When choosing an automatic bagging machine, it is important to consider factors such as the type of product being bagged, the desired bagging rate, the bag size and type, and the level of automation required. Consulting with a reputable supplier can help you select the best machine for your specific needs.