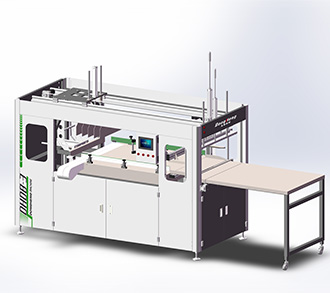

Automatic Bottle Bagging Machine – Model DHDB3

High-Speed Semi-Automatic Packaging for Mass Bottle Production

The DHDB3 automatic bottle bagging machine is engineered for customers who require higher production efficiency while maintaining flexibility and cost control. As a semi-automatic solution, DHDB3 effectively bridges the gap between manual bagging and fully automated systems.

Equipped with Comenster’s flat film bagging technology, this automatic bottle bagging machine ensures smooth bag feeding, precise sealing, and minimal downtime caused by bag breakage or misalignment. The optimized mechanical structure supports long-term stable operation even under high-output conditions.

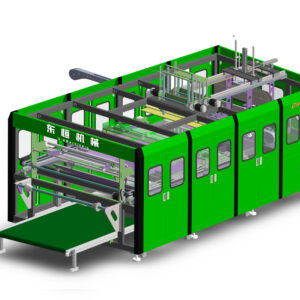

DHDB3 is widely used in beverage factories, edible oil plants, daily chemical packaging lines, and pesticide bottle production facilities. It supports a broad range of bottle shapes, including round, square, and irregular bottles, and can easily adapt to different packaging specifications.

With its intelligent control interface and adjustable bag opening system, DHDB3 allows operators to quickly switch between bottle types and bag sizes. The system is designed to integrate seamlessly with bottle blowing machines, air conveyor systems, and downstream palletizing equipment.

Advantages of DHDB3 Automatic Bottle Bagging Machine

-

Faster production speed for medium-to-large scale factories

-

Automatic bag size adjustment and precise sealing

-

Cold sealing technology with double sealing lines

-

Adjustable bottle feeding and bag opening structure

-

Strong stainless steel pushing platform

-

Touch screen HMI with fault alarm and status monitoring

-

Reduced pallet cost by increasing bottles per layer

-

Enhanced hygiene by minimizing manual handling

Technical Parameters – DHDB3

-

Machine size: 3433L × 1300W × 2600H (mm)

-

Conveyor system: 85mm flexible conveyor (recommended)

-

Weight: approx. 0.7 tons

-

Bag supplying method: Manual bagging

-

Bottle change adjustment: Manual adjustment

-

Applicable bottle materials: PET, PE, PP, HDPE

-

Bottle feeding height: 1050 ±100mm (customizable)

-

Bottle feeding direction: Left / right adjustable

-

Adjustable bottle height: 75–290mm

-

Finished bag package length: 400–1500mm

-

Finished bag package width: 400–950mm

-

Production speed: 3 seconds/row (stable operation), 12 seconds for bag pushing

-

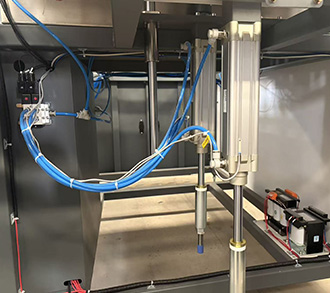

Power consumption: 3kW

-

Power supply: AC 3ψ 380V

-

Air consumption: 0.6–0.8MPa, 0.5m³