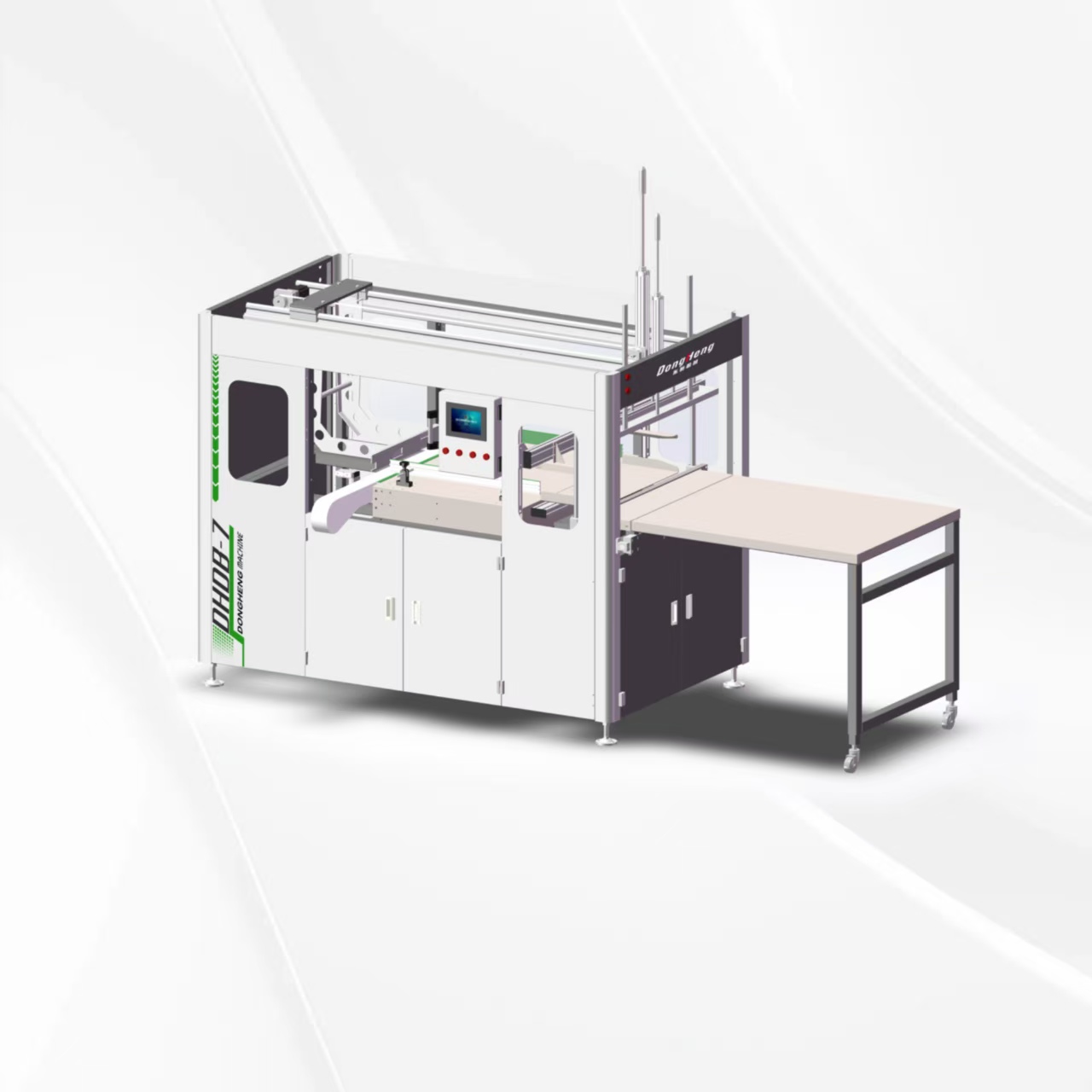

Automatic Bottle Bagging Machine Designed for Large-Volume Bottles

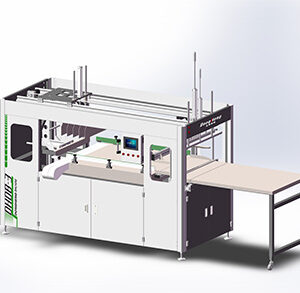

The DHDB7X semi-automatic bottle bagging machine is specifically developed for large-size plastic bottles with extended height requirements. Tailored for production lines handling 1.5L–15L big bottles, this model delivers stable, efficient, and labor-saving packaging performance. With a reinforced mechanical structure and Comenster’s signature flat-film bagging technology, DHDB7X ensures excellent sealing quality without bag tearing or misalignment.

Engineered for Tall Bottles – Suitable Height 175–520mm

Compared with standard models, DHDB7X supports bottle heights from 175 mm up to 520 mm, making it ideal for:

-

Large mineral water bottles (3L, 5L, 10L, 15L)

-

Edible oil containers (3L–10L)

-

Chemical barrels & HDPE jerry cans

-

Wide-mouth large containers used in household products

Its reinforced lifting and pushing platform ensures smooth motion even with heavy bottles, maintaining consistency in high-volume production.

Semi-Automatic Design for Practical, Space-Saving Use

The DHDB7X adopts a semi-automatic bag-loading method:

-

Workers place the bags

-

The machine automatically completes bottle arrangement, pushing, inserting, and sealing

This reduces labor demand while retaining flexibility for various bottle specifications. It can be directly connected to blow molding machines or existing bottle conveyors, making it a reliable upgrade for medium and large factories.

Features of the DHDB7X Large Bottle Bagging Machine

-

Flexible bottle height support: 175–520mm, designed for oversized containers

-

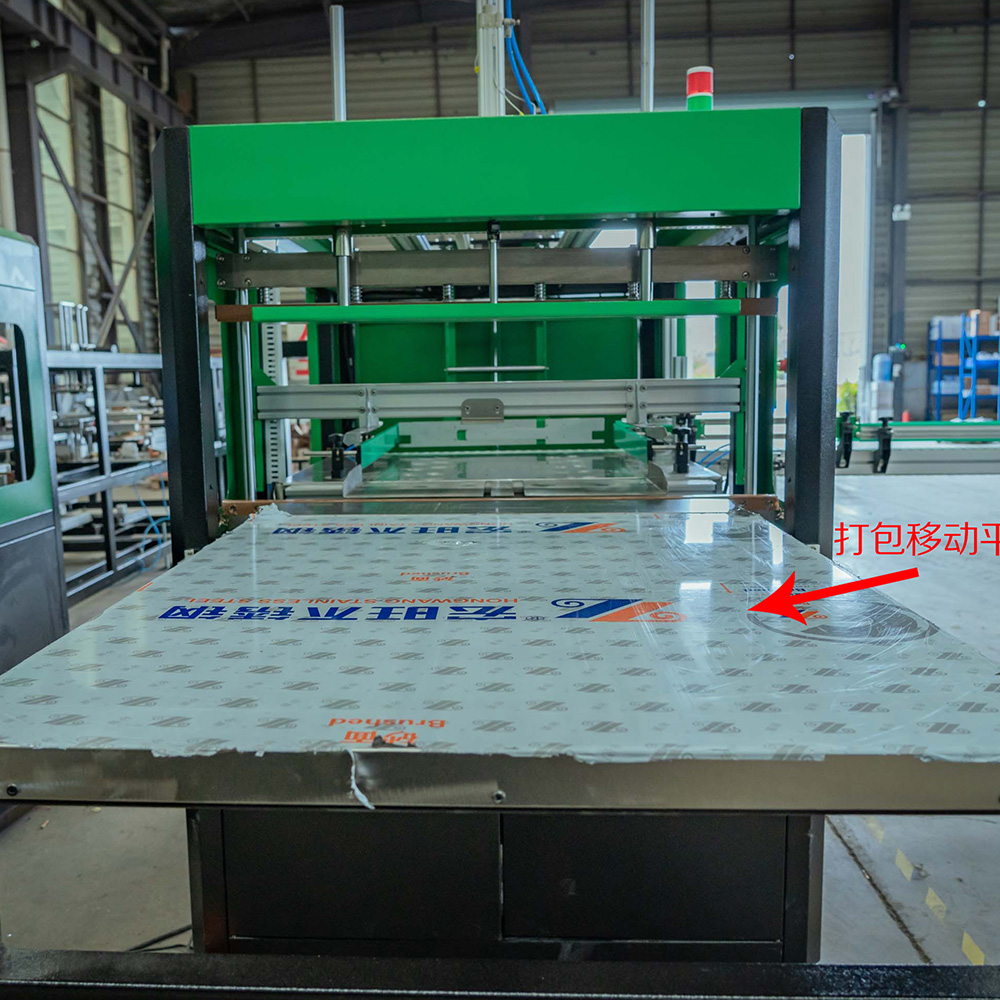

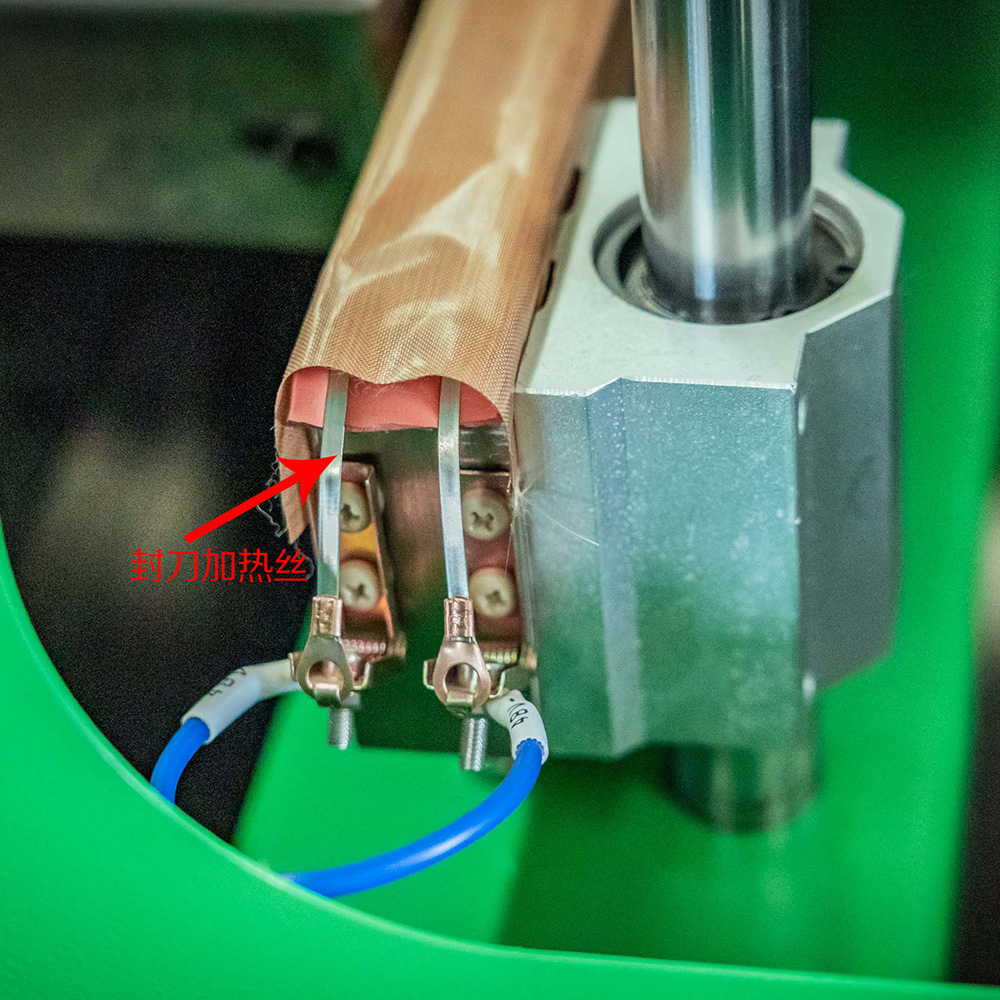

Reinforced dual-sealing knife for thicker bags used in large bottle packaging

-

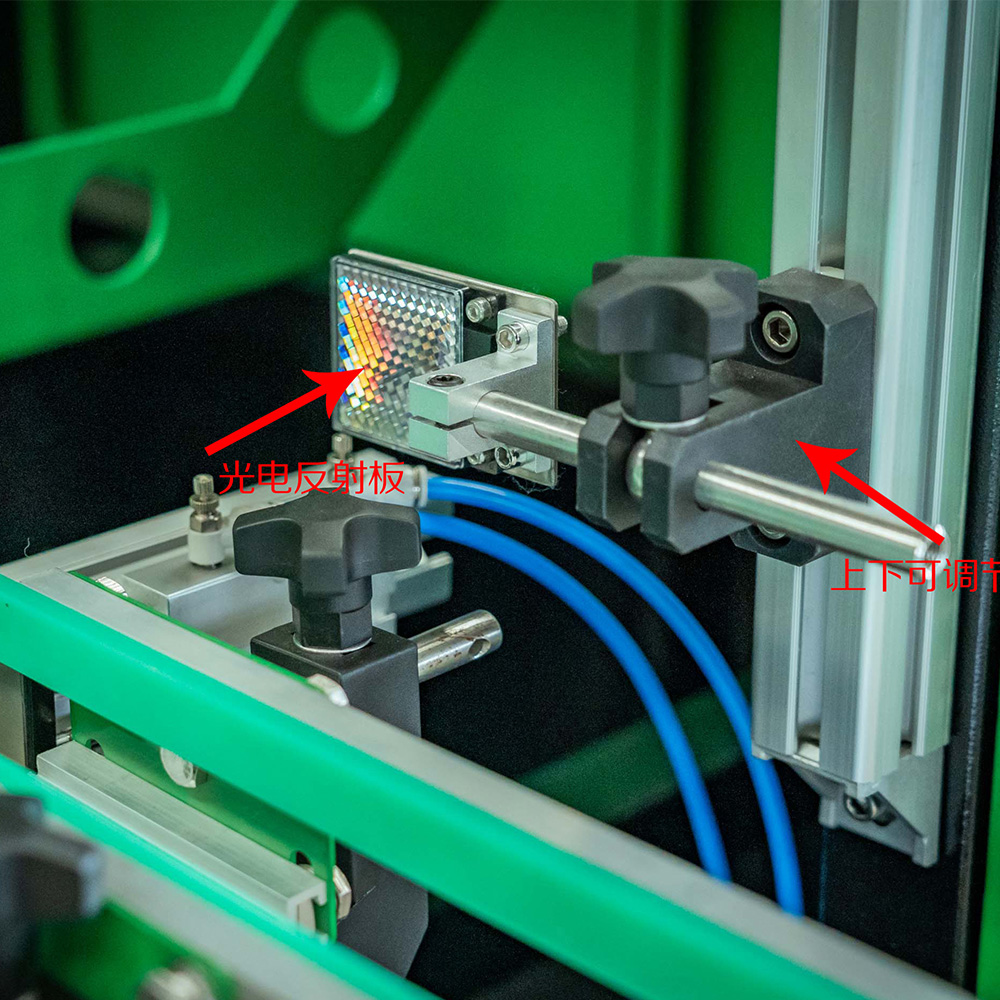

Wide-opening adjustable bag opening system, suitable for heavy-duty flat film

-

Heavy-load stainless steel bottle pushing platform resistant to deformation

-

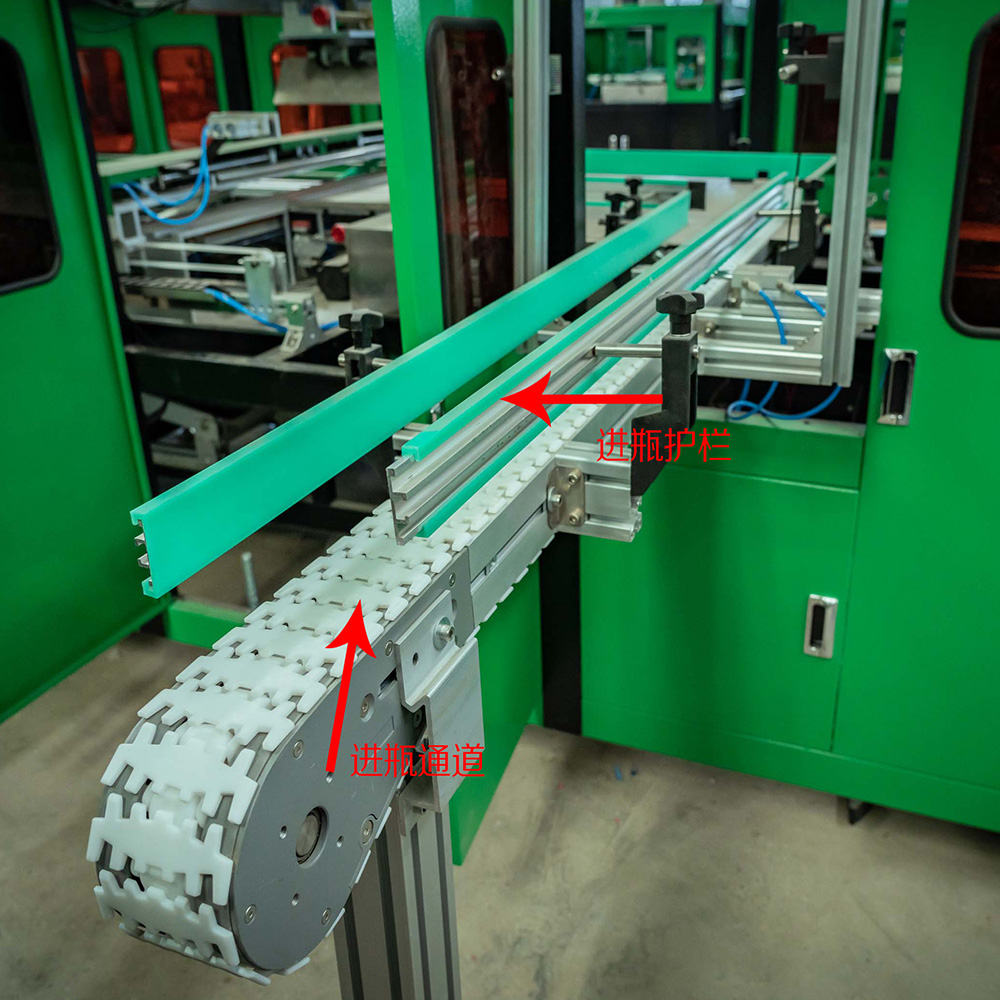

Multi-direction bottle feeding support for layout flexibility

-

User-friendly touch screen with status monitoring & alarm diagnostics

-

Reduces pallet material consumption compared to traditional tray packing

-

Enhances hygiene, protecting bottles from dust and manual contact

Applications

DHDB7X is ideal for large container production lines including:

-

Drinking water & spring water factories

-

Edible oil manufacturers

-

Chemical & detergent bottle producers

-

Barrel-shaped HDPE container plants

Technical Parameters – DHDB7X

-

Machine size: 3433L × 1300W × 2600H mm

-

Conveyor system: 85 mm flexible conveyor system (recommended)

-

Weight: ~0.7 Tons

-

Bag supplying method: manual bagging (semi-automatic)

-

Bottle change mode: manual adjustment

-

Bottle material: PET, PE, PP, HDPE

-

Bottle feeding height: 1050 ±100 mm (customizable)

-

Feeding direction: left / right adjustable

-

Applicable bottle height: 175–520 mm

-

Finished bag length: 400–1500 mm

-

Finished bag width: 400–950 mm

-

Production speed: 3/5/7 seconds/row, 12 seconds for bag pushing

-

Power consumption: 3 kW

-

Power supply: AC 3ψ 380V

-

Air consumption: 0.6–0.8 MPa / 0.5 m³