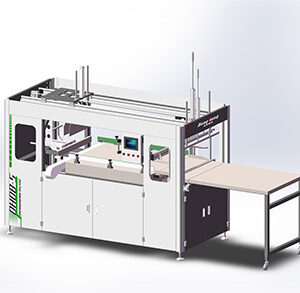

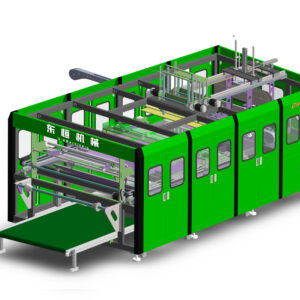

High-Performance Automatic Bottle Bagging Machine for Large-Scale Operations

The DHDB7 automatic bottle bagging machine is built for high-output factories requiring maximum production efficiency. Equipped with upgraded motion control and a reinforced bottle-feeding structure, DHDB7 delivers stable and continuous packaging at industrial speed. Its advanced flat-film technology eliminates bag-opening failures and significantly reduces bag damage rates.

Suitable for Wide Range of Bottle Types and Production Scenarios

DHDB7 can handle PET, PE, PP, HDPE bottles from 200ml up to large 15L containers. It is widely used in water plants, oil factories, cosmetic bottle production, and chemical packaging lines. The machine supports seamless connection with blow molding machines, saving labor and ensuring consistent workflow.

Product Features of DHDB7 Automatic Bottle Bagging Machine

-

Automatic package setting adjustment for multi-format bagging

-

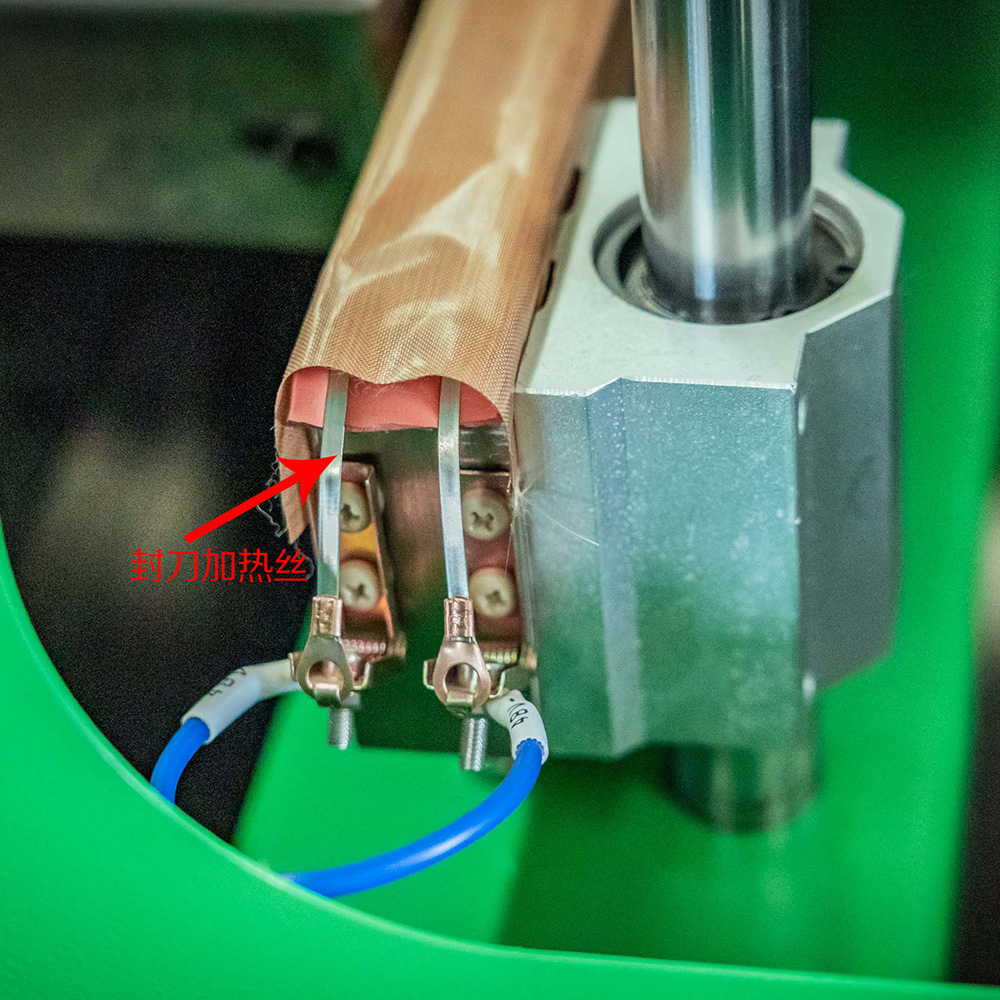

Dual hot-sealing blade system providing strong sealing performance

-

Wide-range bag opening adjustment for different bag materials

-

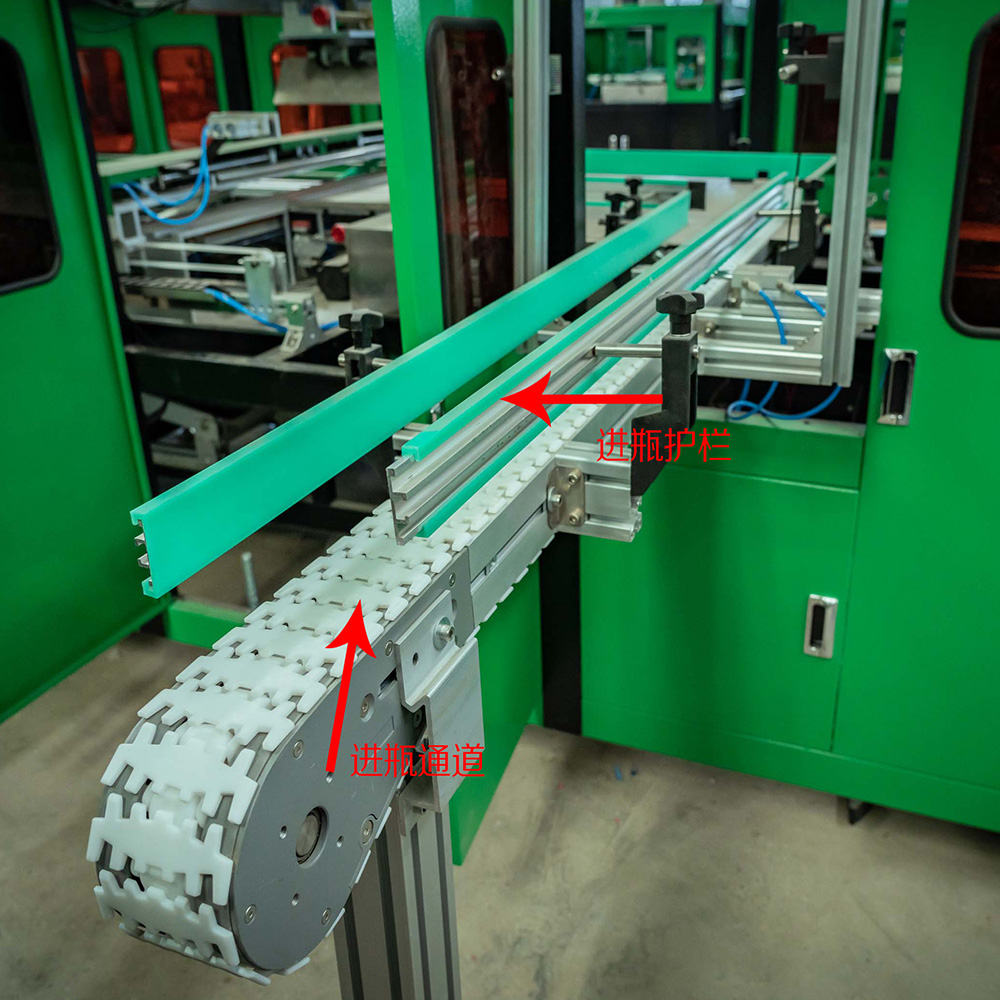

Customizable bottle infeed direction and methods

-

Solid stainless steel pusher platform ensuring durability under heavy load

-

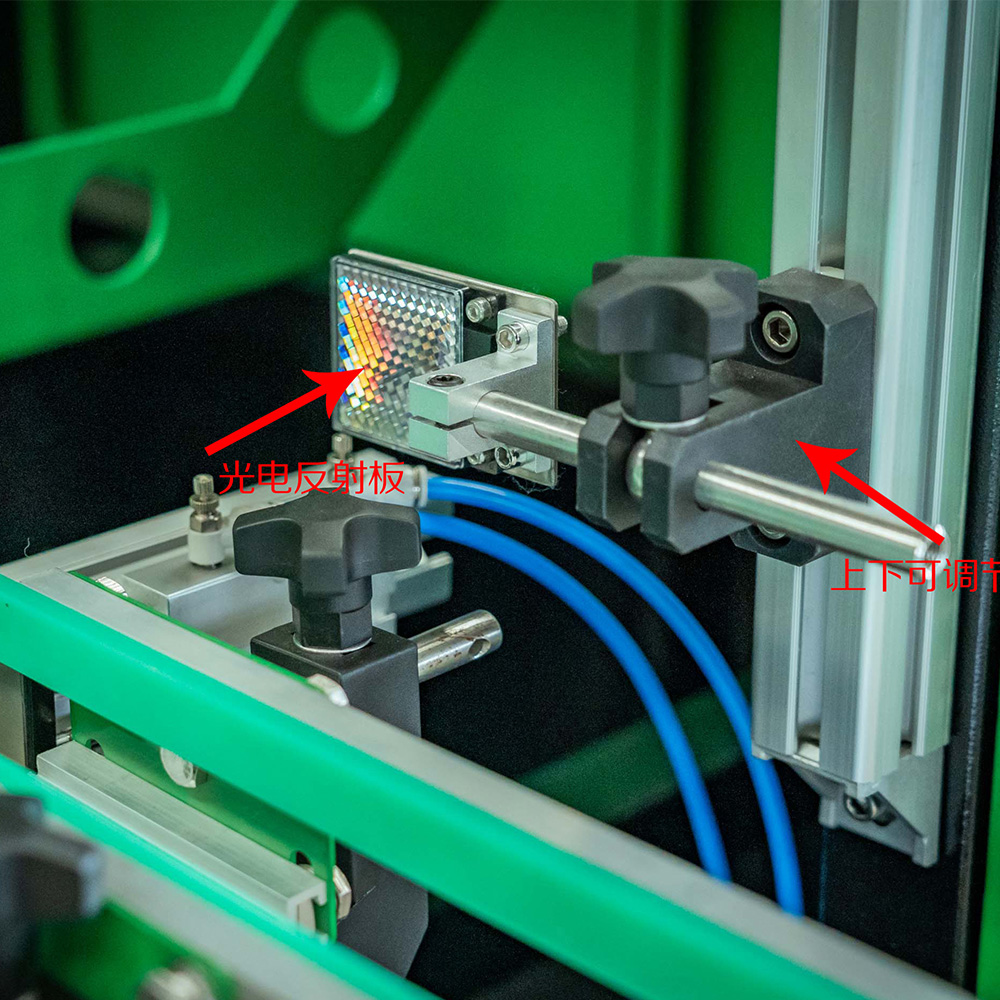

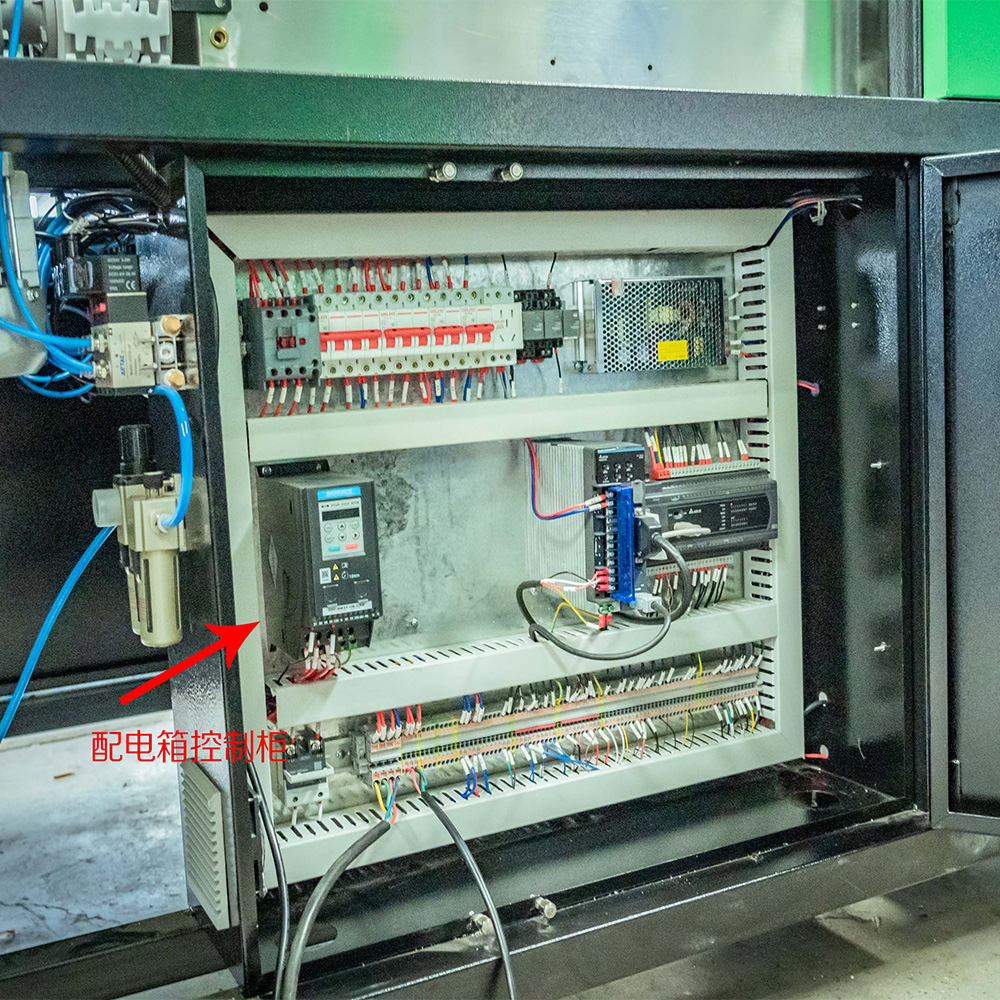

Smart control panel with fault detection & operation monitoring

-

Lower operating costs compared to carton or tray packing

-

Allows more bottles per pallet, optimizing container space

-

Reduced contamination risk, keeping bottles free from dust and manual contact

Technical Parameters – DHDB7

-

Machine size: 3433L × 1300W × 2600H mm

-

Conveyor system: 85 mm flexible conveyor system (recommended)

-

Weight: ~0.7 Tons

-

Bag supplying method: manual bag installation

-

Bottle change mode: manual adjustment

-

Bottle materials: PET, PE, PP, HDPE

-

Feeding height: 1050 ±100 mm (customizable)

-

Feeding direction: left / right adjustable

-

Bottle height: 75–290 mm adjustable

-

Finished bag length: 400–1500 mm

-

Finished bag width: 400–950 mm

-

Production speed: 3 seconds/row, 12 seconds for bag pushing

-

Power: 3 kW, AC 3ψ 380V

-

Air consumption: 0.6–0.8 MPa / 0.5 m³