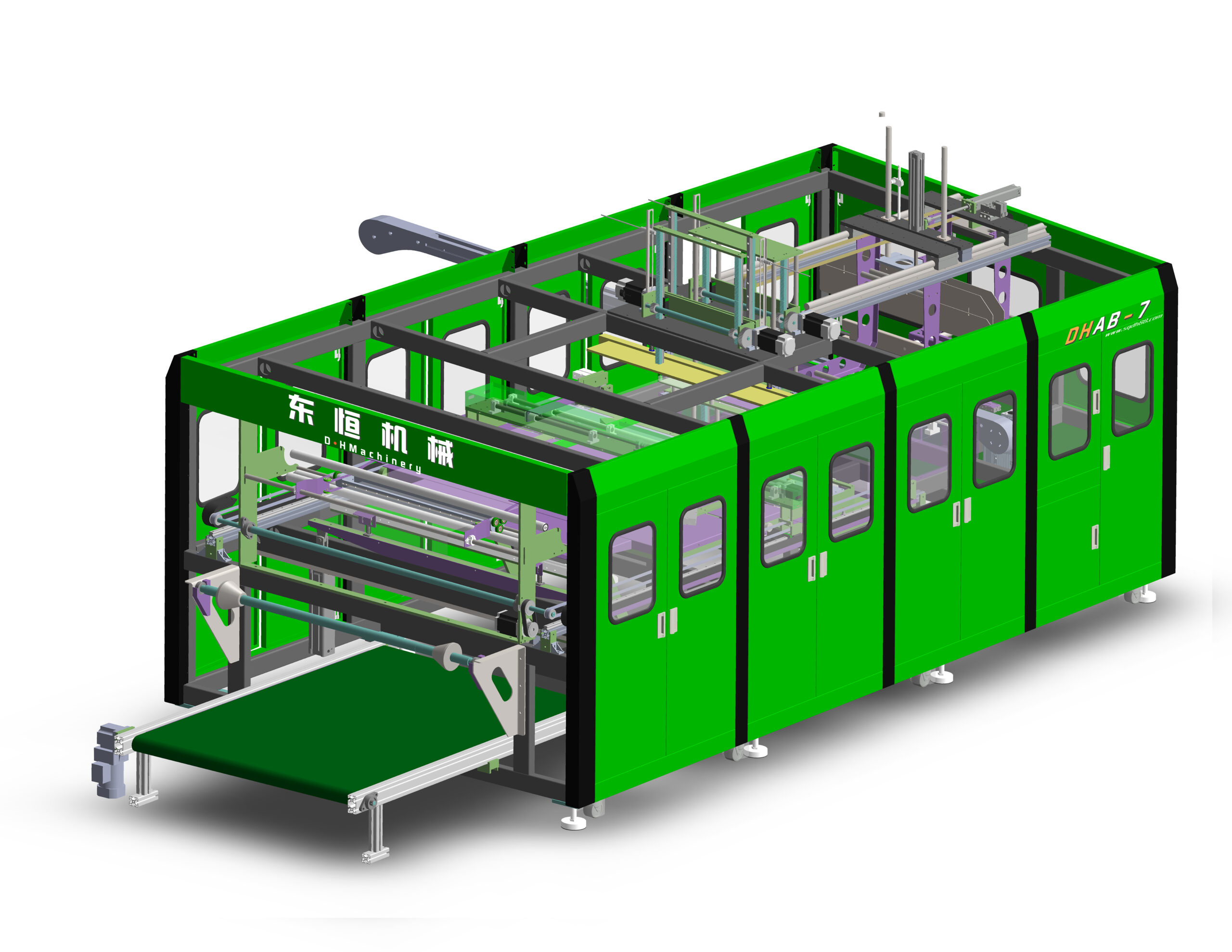

Automatic Bottle Bagging Machine – Smart Packaging Solution for Assembly Line Production

The automatic bottle bagging machine is specially designed for assembly line users who require fast, hygienic and fully automated packaging of various plastic bottles. Suitable for HDPE, PET, PP, PE, PVC and other bottle materials, this system replaces traditional manual bagging and builds a more intelligent, efficient and unmanned bottle packaging environment.

With a compact structure and small footprint, the equipment integrates seamlessly into modern production lines and supports continuous 24-hour operation with minimum labour input.

Compatible With Full Production Line Equipment

The automatic bottle bagging machine can be connected with multiple upstream and downstream machines, enabling a fully automated packaging ecosystem:

-

Bottle blowing machine (PET, PE, PP, PVC)

-

Labeling machine

-

Leakage testing machine

-

Vision inspection system

-

Sorting, conveying and other automated modules

By integrating these systems, manufacturers can move toward an unmanned empty bottle packaging factory and establish an artificial intelligence–driven plastic bottle production platform.

Why Choose an Automatic Bottle Bagging Machine?

1. Fully Automated Packaging

The system completes:

-

Automatic bag feeding

-

Automatic bottle arrangement

-

Automatic pushing into the bag

-

Automatic sealing & cutting

-

Automatic finished bag discharge

No manual contact is required, ensuring a clean and safe hygiene level.

2. Suitable for All Types of Plastic Bottles

This equipment is capable of bagging:

-

Beverage bottles

-

Cosmetic bottles

-

Chemical containers

-

Detergent bottles

-

Medicine bottles

-

Household and industrial HDPE/PET bottles

Bottle height adjustment (75–320 mm) allows fast switching between various bottle specifications.

3. High Efficiency & Labor Saving

Replacing manual packaging significantly:

-

Reduces labor costs

-

Increases line efficiency

-

Improves hygiene safety

-

Supports large-scale, automated production

4. Intelligent Touch-Screen HMI

A user-friendly touch-screen interface enables:

-

Easy operation

-

Real-time monitoring

-

Quick parameter adjustment

-

Safe, hands-free operation

Technical Specifications – Model DHAB3

| Item | Specification |

|---|---|

| Machine size | 5380L × 1950W × 2064H (mm) |

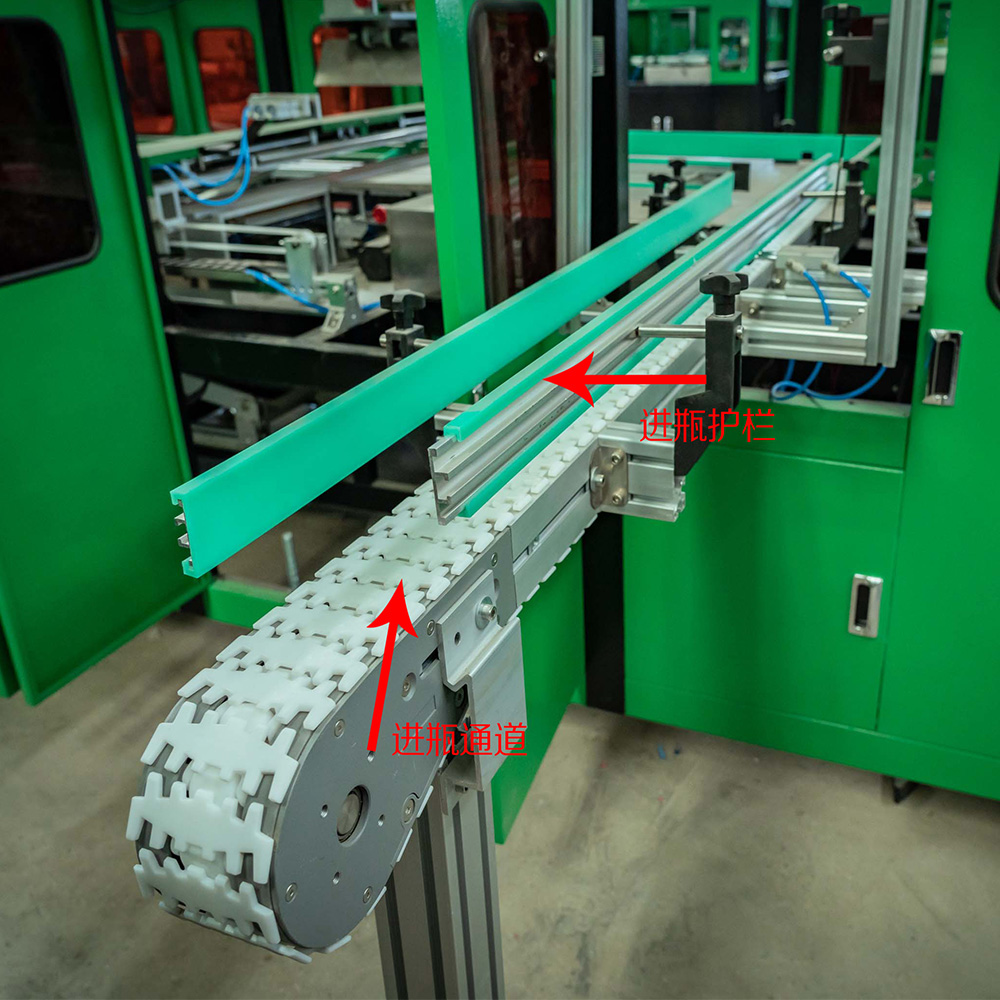

| Conveyor system | 85 mm flexible conveyor (recommended) |

| Weight | approx. 1.3 tons |

| Conveyor height | 1100 ± 100 mm (customizable) |

| Bottle height | 75–320 mm |

| Bottle material | PET, PE, PP, HDPE |

| Production efficiency | ≥95% for 8 continuous hours |

| Bagging method | Automatic plastic bag feeding |

| Maximum package width | 950 mm |

| Production speed | 5 seconds/row (stable), 12 seconds for bag pushing |

| Power supply | AC 3 ψ 380V |

| Power consumption | 4.5 kW |

| Air consumption | 6–8 kg, 0.3 m³ |

| Bottle feeding method | Double-row bottle infeed |